Revitalizing Brazil’s Mature Oil Fields | Innovation and Strategic Operations

For decades, Brazil’s oil and gas production was largely dominated by state-owned Petrobras, particularly in the development of onshore and shallow offshore fields. These mature fields were the backbone of national energy supply throughout the 20th century, laying the foundation for the country’s oil industry. With time, however, many of these assets experienced natural decline in productivity, becoming less attractive to major operators focused on deepwater pre-salt reserves.

This shift opened the door to a new chapter. In the last decade, Brazil has implemented regulatory reforms and asset divestment programs that enabled greater participation from private and independent companies. As a result, a dynamic and competitive market for mature fields has emerged, one that values operational efficiency, creativity, and tailored investment strategies.

Today, Brazil’s mature oil fields are undergoing a strong wave of revitalization. Originally developed by large operators such as Petrobras, Chevron, Shell, and Total Energies, these assets are now being optimized and expanded by a new generation of players. Companies like PRIO, Brava Energia (a joint venture between 3R Petroleum and Enauta), Trident Energy, and Perenco have taken the lead in optimizing and expanding mature field operations, especially in offshore environments with subsea infrastructure. These operators are applying advanced production technologies, including subsea well interventions, tiebacks to existing FPSOs, and digital reservoir monitoring systems, to unlock remaining potential from aging assets.

Other emerging players such as PetroReconcavo, Origem Energia, and Eneva are also making significant contributions, primarily onshore, but with growing interest in near-shore and marginal subsea developments.

Together, these companies are transforming the mature field segment in Brazil into a dynamic, innovation-driven arena that blends engineering rigor with operational flexibility.

These operators are bringing a fresh mindset to the table, one that embraces agility, technology, and “outside-the-box” thinking. Enhanced Oil Recovery (EOR) strategies, subsea equipment refurbishment, well workovers, and data-driven decision-making are just some of the tools being employed. Many of these players are also open to partnerships with engineering firms and technology providers to accelerate implementation and reduce OPEX.

This wave of revitalization is not only unlocking value from previously overlooked reservoirs but also contributing to Brazil’s broader energy security and production targets. Mature field development is no longer seen as a secondary effort, it is now a strategic focus in the country’s energy mix.

Systems Engineering Strategies for the Revitalization of Mature Oil Fields

Mature oil fields present complex challenges that require integrated, multidisciplinary solutions. Declining reservoir pressure, aging infrastructure, reduced production efficiency, and increasing operational costs demand a strategic engineering approach. Systems Engineering (SE) provides a structured framework for the revitalization of these assets, balancing technical, operational, economic, and regulatory requirements to extend field life and maximize value.

Systems Engineering is a holistic methodology that emphasizes the integration of various disciplines to manage complex systems throughout their life cycles. In the context of mature field revitalization, SE enables:

- Comprehensive asset analysis

- Lifecycle-focused planning

- Stakeholder alignment

- Optimization of resources and infrastructure

- Risk identification and mitigation

Infrastructure Upgrades and Flow Assurance Analysis

Aging surface and subsea infrastructure in mature fields often requires significant retrofitting to support modern production conditions and mitigate flow risks. Among the most critical challenges is hydrate formation, especially in subsea tiebacks, low-pressure wells, and areas with long flowlines operating in cold conditions.

Advanced Flow Assurance Strategies Include:

- Low-Dosage Hydrate Inhibitors (LDHIs): These modern inhibitors, classified as kinetic hydrate inhibitors (KHIs) and anti-agglomerants (AAs), are increasingly replacing conventional thermodynamic inhibitors like methanol or nonethylene glycol (MEG). They are more efficient in lower dosages, reducing chemical logistics and CAPEX for injection systems.

- Intelligent Chemical Injection Systems: Smart injection systems equipped with flow sensors, adaptive algorithms, and remote actuation allow precise dosing of inhibitors based on real-time data, reducing waste and ensuring continuous protection under dynamic flow conditions.

- Heat Management Solutions: In some cases, electrically trace-heated pipelines or active insulation can be deployed in key segments to maintain temperature above hydrate formation thresholds.

- Slug Control and Fluid Conditioning: Through pigging systems, separation units, and slug catchers, operators can better manage water cut and emulsions that increase hydrate risks.

These flow assurance strategies, when implemented through systems engineering, are integrated with production planning and SCADA platforms to support predictive control and fast response to hydrate formation events.

Artificial Lift Optimization in Low-Pressure Environments

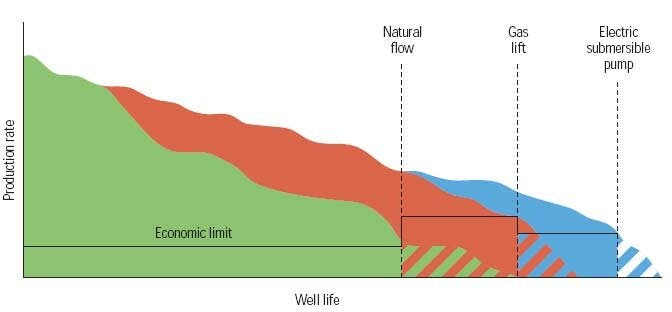

Artificial Lift is essential to maintain and enhance production in mature fields, where natural reservoir drive has declined significantly. The choice of lift method depends on fluid properties, reservoir depth, well architecture, gas content, and OPEX considerations.

Key Artificial Lift Technologies Applied in Revitalization Projects:

- Electric Submersible Pumps (ESPs): Ideal for high-rate wells, modern ESP systems can be installed with variable speed drives (VSDs) and downhole sensors to optimize lift dynamically. New high-temperature and multiphase-tolerant designs have expanded ESP use in challenging conditions.

- Gas Lift (Continuous and Intermittent): Favored for wells with gas availability and lower lifting costs, gas lift is often revitalized with digital control valves and automated gas injection metering systems. It’s particularly suited for offshore mature fields with infrastructure already in place.

- Rod Pumping Units (Beam Pumps): Common in onshore revitalization, especially in shallow wells with high viscosity fluids. Recent innovations in automation and predictive maintenance (e.g., polish rod load cells and AI-based diagnostics) have extended the operational life and efficiency of these systems.

- Hydraulic Pumping Systems: Useful in deviated or horizontal wells where rod pumping is limited. Compact surface units and intelligent subsurface assemblies provide flexible solutions for brownfields with constrained footprints.

- Plunger Lift Systems: Economical solutions for wells with intermittent production or liquid loading problems. These systems can be enhanced with smart controllers and pressure monitoring for real-time optimization.

A systems engineering approach considers not only the lift method but its integration into the entire production system, including power supply, chemical injection, surface handling, and reservoir surveillance. Lifecycle analysis and digital twins help operators simulate multiple lift strategies before implementation, optimizing ROI and minimizing downtime.

+NR is fully aligned with this global movement. Revitalizing mature fields is a multifaceted engineering challenge, and a significant opportunity for production recovery and long-term value creation. From Brazil to international offshore basins, we are supporting operators with advanced Artificial Lift solutions and intelligent flow assurance strategies. When integrated through a systems engineering approach, these technologies can unlock substantial production gains and extend the life of aging infrastructure.

Our footprint is growing across key mature field regions worldwide. In addition to our strong presence in Brazil, +NR is actively supporting operators in Malaysia, Angola, and the North Sea, delivering tailored lift solutions, hydrate mitigation systems, and brownfield engineering expertise. Our multidisciplinary team combines cutting-edge technology with data-driven methodologies to help clients recover production, reduce intervention frequency, and sustainably expand the life cycle of mature assets, anywhere in the world.