Materials Handling Engineering | Efficiency and Reliability from Mine to Plant

At Plus Natural Resources (+NR), we apply our multidisciplinary engineering expertise to turn operational challenges into lasting solutions in materials handling. From ore reception to plant feed, we design robust, safe, and adaptable systems tailored to the specific needs of each operation—whether in brownfield upgrades or greenfield developments.

Through field diagnostics carried out in several mines across Brazil, Africa, India, Europe, and beyond, we identify critical factors that must be addressed from the earliest project phases to ensure long-term productivity, operational continuity, and reduced maintenance costs.

Improvements in Existing Plants (Brownfield Projects)

In ongoing operations, shifts in ore characteristics, natural equipment wear, and pressure for capacity increases require strategic corrective actions. Our brownfield work begins with a comprehensive process analysis, including:

- Review of the mass balance and volumetric performance: We assess the balance between inputs and outputs at each stage of the plant, identifying bottlenecks, asset underutilization, and operational risks;

- Assessment of buildup and real flow behavior in silos, chutes, conveyors, and hoppers, considering variations in density, moisture, stickiness, and particle size over time.

Based on this data, we deliver engineered solutions such as:

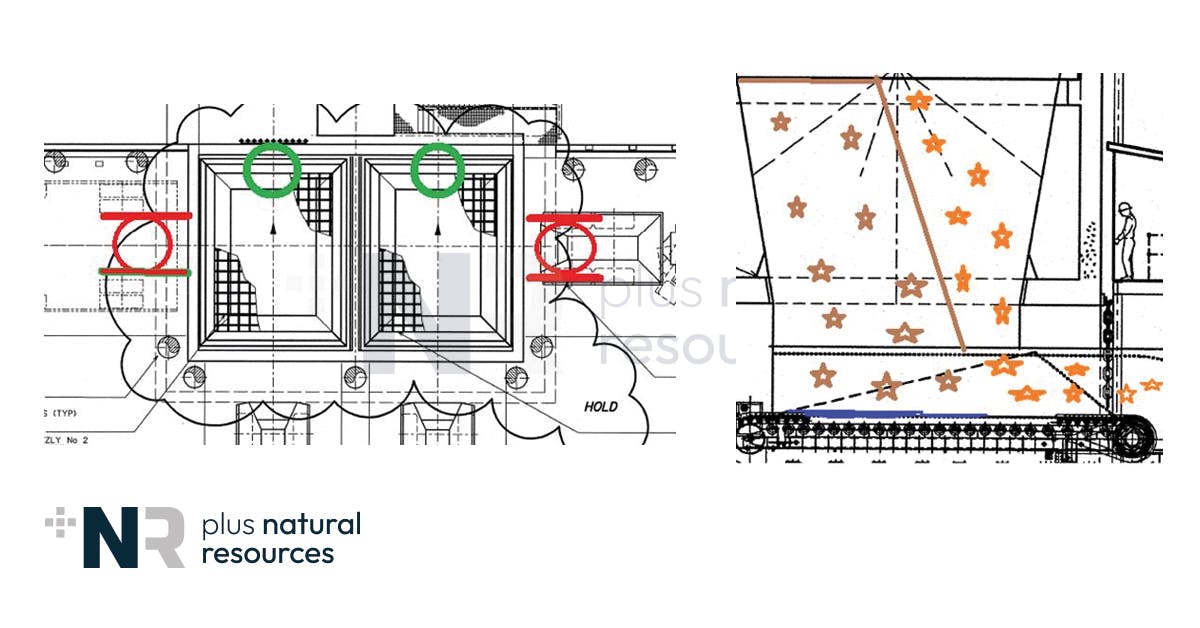

- Redesign of hoppers and discharge points to improve geometry, flow behavior, and surge capacity;

- Optimization of apron feeders with new geometries, traction bars, rubber curtains, and air cannons;

- Replacement of crushers with scalping screens, reducing wear and energy consumption;

- Implementation of single-line operation with active redundancy, enabling preventive maintenance without interrupting plant feed;

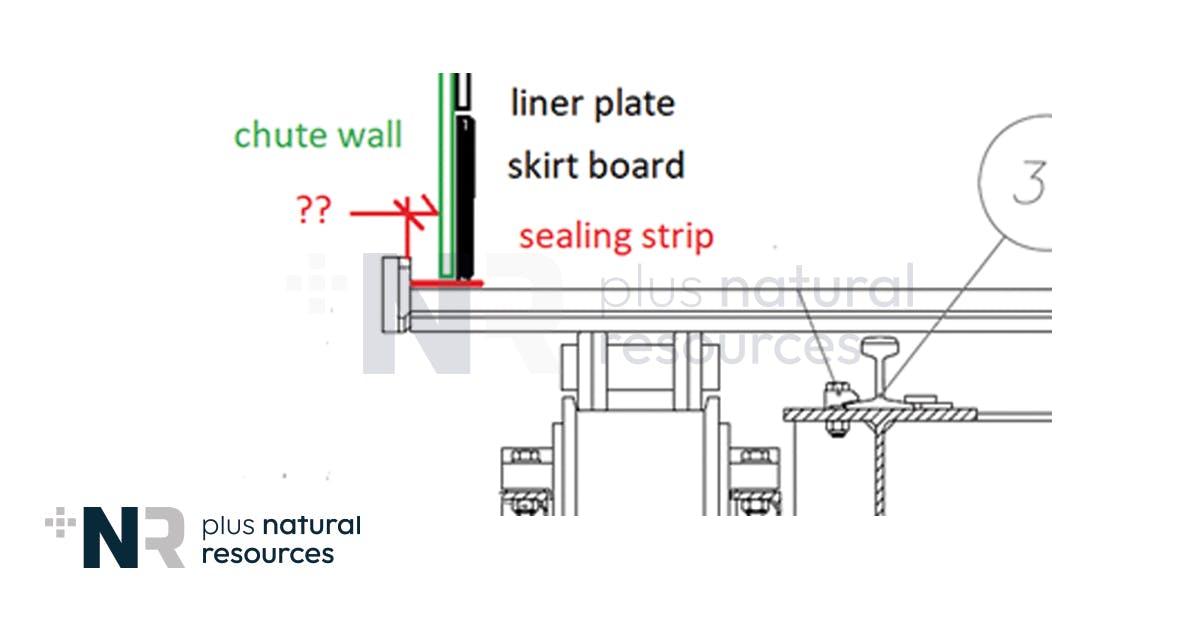

- Installation of scrapper conveyors, sealing improvements, and better spill recovery systems;

- Application of variable frequency drives (VFD/VVVF) to conveyors and feeding systems, enabling dynamic load control and energy efficiency;

- Wear testing and material selection adapted to ore type and local environmental conditions.

These interventions are designed to boost performance, reduce losses, and increase operational reliability, with optimized CAPEX and feasible execution schedules for running facilities.

Greenfield Project Development

In new developments, materials handling is a foundational element of conceptual design. Our process starts with a strategic technical assessment of the logistics and operational systems, including:

- Development of the mass balance for the crushing, conveying, and plant feeding systems;

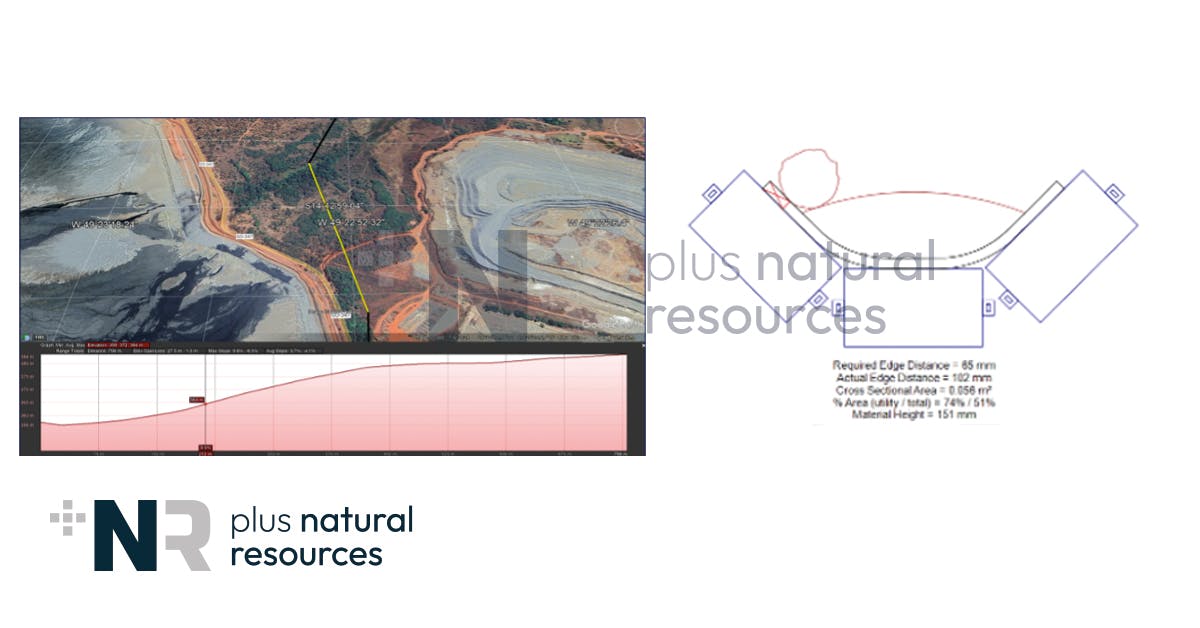

- Volumetric simulation of buffers, hoppers, and conveyors, considering normal, peak, and contingency operating conditions;

- Integration with other plant subsystems, such as mining operations, primary crushing, stockyards, and the processing plant.

From this solid data foundation, we engineer tailored solutions, including:

- Complete ROM area design, with elevated truck platforms, grizzlies, dump stations, chutes, and apron feeders suited to the ore profile, humidity, density, and hauling fleet;

- Definition of buffers and decoupling elements, such as surge silos or intermediate stockpiles to stabilize plant feed;

- Design of long-distance conveyor systems, incorporating optimized routing that accounts for water crossings, topographical constraints, and the strategic placement of transfer stations, as well as integrated cleaning and drainage solutions;

- Primary scalping screens instead of crushers, when ore characteristics or metallurgical requirements make it advantageous;

- Modular and scalable layouts, enabling progressive capacity expansion throughout the mine’s lifecycle;

- Auxiliary infrastructure, including drainage, access roads, ventilation, and environmental containment systems.

Our strength lies in integrating process modeling with civil, structural, mechanical, and electrical disciplines, ensuring every design decision is technically sound, economically viable, and operationally effective.

A Partner for Real-World Challenges

Whether you are expanding an existing plant or building a new operation, +NR’s materials handling engineering is driven by operational data, structured analysis, and practical solutions. Our projects combine technology, sustainability, and reliability, always with a long-term vision.

If your operation is facing bottlenecks, excessive equipment wear, sticky ore flow issues, or needs to rethink its expansion strategy, talk to our team. We turn project challenges into real results.